Introduction

The trend of increase, in the course of time, of the extraction of mineral deposits, obtainment and use of various mineral production [1,2] in modern conditions is accompanied in the majority of cases and in many countries, including Russia with its Far Eastern region, by essential reduction of the quality of both natural and residue mineral raw materials extracted and used [2,3]. Specifically, over the last 25-30 years, the content of iron in ore has dropped nearly 1.3 fold [1,2], in ores of noble metals, mainly gold, — approximately 1.3 - 1.8 fold [2].

This is due to a row of objective and subjective factors.

The reduction of quality of ores and some other high-demand mineral deposits is conditioned by the following main reasons:

1. The mining of the so called rich deposits and the involvement (in growing numbers) in the development of mineral features with relatively low content of commercial components. For example, often residue placers with gold content of up to 80 mg/m3, natural placers — with gold content of up to 1 - 1.3 g/m3 are mined by dragging.

2. Forced development of deposits of complex, the so called refractory ores.

3. High non-uniformity of material composition of natural and residue deposits involved in mining.

4. Imperfection of widely used traditional technologies of mineral deposits extraction during the use of which high impoverishment of mineral raw materials extracted, often reaching 15 - 18%, occurs in the course of extraction [4].

In these conditions, primarily reasonable forming and extracting within deposit mined areas in relation of uniformed components (mini- and meso-producing blocks) as well as their subsequent separate selective mining gains great significance. Such deep selectivity of mining is necessary to ensure process uniformity of mineral matter coming to processing and/or metallurgical treatment via either subsequent averaging in optimal ratios of its components and treatment in bulk as per same diagram or separately with various modes and parameters. In the most complex areas, in case of sufficient difference in mineral composition, grain size, deportment of commercial components, selectively mined rock mass undergoes separate processing as per relevant process diagrams. The uniformity of such mined elements is proposed to be terminologically expressed by “process mineral uniformity” category. In respect to mining field, it is feasible to use “process mineral uniformity” terminological category.

Scientific and practical justification

It should be noted that the introduction of “Mining and mineral uniformity” category does not substitute for relatively widely used “Process mineralogy” category [5] which, as it will be shown further, represents (in its own purpose) rather essential part of “Mining and mineral uniformity” category if broadly defined as specific scientific and production activity (fig. 1).

Mining and process mineral uniformity

|

|

Fig. 1. The content of general category — “mining and mineral uniformity” in terms of main functionality of scientific and production and training activities

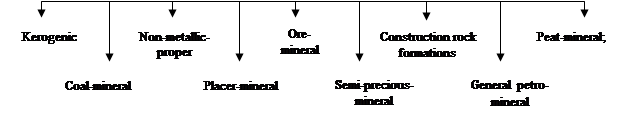

In terms of general aggregateness, we put forward the following categories of mineral uniformity of mining and geological features: natural-gas-mineral; petro-mineral; mineral-proper; liqua-mineral to which it is reasonable to refer the oil-mineral uniformity and brine-mineral uniformity; construction-rock; hydro-mineral and peat-mineral ones.

The categories of substantial and industry mineral uniformity are represented schematically in fig. 2

Substantial and industry mineral uniformity

Fig. 2. The categories of mineral uniformity distinguished in general substantial and industrial aspect

By the origin of initial mineral features of mineral uniformity we distinguish its following general categories:

I. Mineral uniformity of natural mineral features.

II. Mineral uniformity of residue mineral features.

III. Mineral uniformity of natural and residue mineral features which, primarily, include previous pillars, mineral sub-levels, mineral masses and their components in marginal part of open-cuts, coal and schistic open pits.

Distinguished mineral uniformity categories are represented, by some other important attributes, as schemes (fig. 3-5) and text.

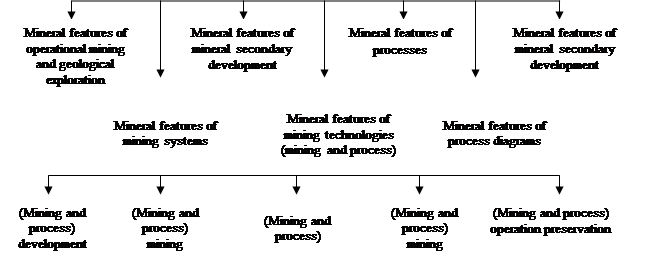

At present, production-staged mineral uniformity the initial composition of which is schematically represented in fig. 3 gains great importance.

Mineral uniformity

|

Fig. 3. The initial composition of mineral uniformity in terms of main categories of productive mineral objects

Mineral uniformity

Mineral uniformity

Fig. 4. Initial composition of mineral uniformity in terms of mineral features of production operational and process stages

Mineral uniformity main subcategories being distinguished in terms of spatial tracking of mineral features have physical and geographical, geological proper, geophysical, geochemical rather complex spatial tracking from the perspective of effective extraction of their mineral features; quantitative mineral uniformity; quantitative chemical and elemental uniformity; quantitative mineral uniformity; quantitative complex and substantial mineral uniformity.

Quantitative and qualitative mineral uniformity is a uniformity characterized by modern qualities and quantitative peculiarities, i.e. the exhibition of these peculiarities simultaneously in reference to each other.

Mineral uniformity

Fig. 5. The composition of mineral uniformity in terms of key properties of mineral and geochemical substantivity

[”Mineral” sub-term means possible fossils, primarily solid minerals, specifically – ore, coal, etc.]

|

|

The uniformity of mineral features of processes of development and mining of commercial minerals deposits (especially ore ones) is greatly diverse and includes:

1.Operational geological exploration.

2.Failure and loosening of rock formations.

3.Extraction-and-loading.

4.Operational failure of rock formations and boulder.

5.Mineral secondary development.

6.Transportation of rock.

7.Stockpile and dumping.

8.Primary processing (mainly, beneficiation).

In terms of complex quantitative and qualitative peculiarities of mineral features, the composition of mineral uniformity (in many-fold expression) is represented in the shape of the following original subcategories:

I. Qualitative mineral uniformity with which the quality of gold ores comes out in the following features [6,7]:

– the level of gold content in mineral features and formations;

– irregularity of distribution of gold in them;

– grain size of gold and difference gold grain shapes;

– mineral fineness of gold and other quality parameters.

II. Quantitative mineral uniformity which is not that diverse in its exhibition and comes down, specifically, to the following subcategories of uniformity: qualitative mineral uniformity – ore, of main substantive and applicative purpose: quantitative geochemical, qualitative geophysical The composition from the perspective of general substantial mineral uniformity in terms of its main properties is such.

III. Quantitative and qualitative mineral uniformity is uniformity. Characterized by integrated qualities and quantitative peculiarities, i.e. the exhibition of these peculiarities simultaneously in reference to each other.

IV. General substantial and process mineral uniformity.

V. Process physical and mineral uniformity which uniformity of physical properties of mineral features and formations are mainly referred to, and as a whole — geophysical properties of mineral features and formations.

VI.Process chemical and mineral uniformity, including geochemical uniformity.

VII.Process physical and chemical and mineral uniformity;

VIII.Process mineral and technical uniformity, i.e. Uniformity of technical properties of mineral features and formations.

Results

Mineral uniformity is first introduced and justified as new and currently important scientific and production category in the field of mining and the development of mineral features in particular. Meaning of and the necessity of the use of terms “mineral uniformity of natural” and “natural and technical mineral features” has been accordingly disclosed and justified, relative mineral uniformity of mineral features of development and mining within natural and natural and residue mineral formations being formed and distinguished has been considered.

|

|

Conclusions

The following may be assigned to basic conclusions:

Mineral uniformity is one of the most important categories of scientific and production activity in the field of effective development of mineral formations and features and subsurface use as a whole.

The achievement of mineral uniformity for the account of deep differentiation of mass mined distinguishing meso- and micro-features of mining and its implementation in in mining industry become significant importance in present-day conditions, ultimately, from the perspective of securing a row of process, economical and some other aspects of mineral deposits development. Primarily, its role is important in an increase in the completeness of mining and the quality of mineral raw materials, mineral products made of them; the enhancement of labour culture and various minerals production facilities, significant reduction of energy consumption of processes and the development as a whole; cutting of capital and operational expenditures; increase of manpower productivity; reduction of social and economic and ecological costs of mineral production facilities; increase in the complexity of using fossils and mineral resources and subsoils as a whole.

The composition and structure of mineral uniformity of features of mining technologies and process diagrams have been established in hierarchic sequence and in volume (using basic attributes system complex).

Based upon the use of system mineral uniformity of mineral features, it turns out to be practical to accomplish reasonable modernization of traditional and creation of innovative mining technologies for deposits development.

List of references

1. Grovson P.C.F. Miberals handbook 2000-01 Stanstic analyses of the worids minerals indystry/ Endinbridge.Miningjornalbooks/ 2001.

2. G.I. Arkhipov Mineral resources of ore mining industry of Far East. Review of state and possibility of development. – M.: “Mining book”. 2011. - page 830. – (Mining book – Far East).

3. A.P. Van-Van-E Resource potential of natural and residue gold ore deposits. – M.: “Mining book”. Moscow State Mining University Publishing house. pp. 2010-268 (Mining book – Far East).

4. G.V. Sekosov, N.V. Zykov The development of mineral features and evaluation method. – M.: “Mining book” Publishing house, - 2012. pp 295-311.

5. Mining sciences. The development and depletion of entrails of the Earth./edited by K.N. Trubetskoi. – M.: Mining sciences academy Publishing house. 1997. pp 392-394.

6. S.A. Bushmin, B.V. Belyavsky, V.A. Glehovskiy, A.K. Borko ISOCHRON RF-OS AGE of gold from Magskoe gold-Quartz vein dein deposit (Northern Karelia. Balticsheld).DokladyEarthSeiences. 2013. T. 448. No.1. pp 54-57.

7. G.V. Sekosov, A.A. Sobolev, E.V. Nigai Types of gold ore deposits of Far Eastern region and main directions of their regional development//Mining information-analytical bulletin – 2011iu-No.2. – pp 192-201.

Подпись руководителя практики от предприятия ________________