Department of Power supply of industrial enterprises

Course work

On discipline: Electric power supply

On theme: Calculation of electrical loads and making workshop networks schemes

Done by: st. of group EE-13 Sydykova N.N

№ of record book: 134140

Checked: Soltanayev A.M

«____» ___________________ 20___y.

Almaty, 2016

Contents

| Task for coursework | ||

| Table 1 – Initial data for option 40 | ||

| Table 2 - Initial data of the workshop | ||

| The calculation of the initial data of workshop | ||

| The calculation of electrical loads of workshop. | ||

| Calculation of lighting load of the workshop | ||

| Table 4 - The calculation of loads on the workshop | ||

| Table 5 - Technical data of electroreceivers | ||

| The calculation of the technical data for power consumers and the choice of protective devices | ||

| The choice of circuit breaker, cable and type of busways | ||

| Table 7 - Calculation of protective devices to ER | ||

| Table 8 – Calculation protective devices to DB, DBW, LL, DMBW | ||

| Calculation of short circuit currents | ||

| Calculation of resistance on the circuit area | ||

| Calculation of short circuit on the circuit areas | ||

| CONCLUSION | ||

Task for coursework

For one of the workshops of the industrial enterprise is required to perform the following measures:

1 Mark out the supplying nodes of the electrical receivers ER (power boards, distribution busways).

2 Determine the power loads at supply nodes, lighting load and design load of whole workshop with method of utilization factor and maximum coefficient.

3 Select a scheme of supply and distribution network of workshop.

4 Select a number and capacity of transformers, place of location for workshop substation.

5 Determine a section and type of wires, cables and busbars in workshop network.

6 Choose electrical equipment and calculate currents of fuse-links and tripping setting of circuit breaker.

7 Draw a plan of electrical power network of the workshop.

8 Draw a scheme of power supply and distribution network of workshop with the indication of section of wires, cables, and parameters of shutdown and protective equipment and electrical receivers.

9 Specify parameters of the network, protection devices, the neutral wire from complete transformer substation (CTS) to the most remote powerful electric motor, design and peak currents in the designed single line scheme of supply and distribution networks up to 1 kV of the workshop.

10 Determine the three, two and single-phase short-circuit currents in the designated point K1, K2 and K3. Assume conditionally the short-circuit power at the high side of workshop transformer in the range 100¸150 MVA. Calculate twice the single-phase short circuit: at the transformer scheme D/Uо - 11 and the scheme U/Uо - 12.

Table 1 – Initial data for option 40

| № by plan | № of task | |

| Name of equipment | Installed power of electroreceivers (kW) | |

| 1,2 | Vertical milling | |

| 3,4,21,22,25 | Chamber electric furnace | |

| 5,23,24 | Bell-type electric furnace | |

| 6,7 | Mortising | |

| 10,11,18 | Hull-grinding | |

| 9,12,13,33 | Screw-cutting | |

| 14,27 | Circular shears | |

| 8,16,17 | Circular grinding | |

| 19,20 | Crank Press | |

| Induction furnace (kVA) | ||

| 28,29 | Shaping-machine | |

| 34,38 | Radial-Drilling | |

| 31,32 | Automatic lathes | |

| 15,30 | Crane with DR-40 % | |

| 35,36,37 | Horizontal milling | |

| Plasma heating machine | ||

| Butt-welding machine with DR-25 % (kVA) | ||

| Electric fan |

Figure 1 – Plan of thermal workshop

Table 2 - Initial data of the workshop

| № | Name of supply nodes | Installed capacity, kW | Mode | Factors | ||

| Ки | cosφ | tgφ | ||||

| 1,2 | Vertical milling | medium start | 0,16 | 0,6 | 1,33 | |

| 3,4,21,22,25 | Chamber electric furnace | - | 0,6 | 0,95 | 0,32 | |

| 5,23,24 | Bell-type electric furnace | - | 0,6 | 0,95 | 0,32 | |

| 6,7 | Mortising | medium start | 0,12 | 0,5 | 1,73 | |

| 10,11, | Hull-grinding | easy start | 0,12 | 0,5 | 1,16 | |

| 9,12,13,33 | Screw-cutting | medium start | 0,16 | 0,6 | 1,33 | |

| 14,27 | Circular shears | medium start | 0,16 | 0,6 | 1,33 | |

| 8,16,17 | Circular grinding | hard start | 0,25 | 0,65 | 1,16 | |

| 19,20 | Crank Press | medium start | 0,16 | 0,6 | 1,33 | |

| Induction furnace (kVA) | 35,75 (55) | - | 0,25 | 0,65 | 1,16 | |

| 28,29 | Shaping-machine | hard start | 0,25 | 0,65 | 1,16 | |

| 34,38 | Radial-Drilling | easy start | 0,12 | 0,5 | 1,73 | |

| 31,32 | Automatic lathes | easy start | 0,12 | 0,5 | 1,73 | |

| 15,30 | Crane with DR-40 % | 13,91 (22) | medium start | 0,25 | 0,5 | 1,73 |

| 35,36,37 | Horizontal milling | medium start | 0,16 | 0,6 | 1,33 | |

| Plasma heating machine | hard start | 0,25 | 0,65 | 1,16 | ||

| Butt-welding machine with DR-25 % (kVA) | 17,5 (50) | medium start | 0,25 | 0,7 | 1,02 | |

| Electric fan | hard start | 0,6 | 0,8 | 0,75 |

The calculation of the initial data of workshop

15, 30) Crane with DR-40 %  :

:

26) Induction furnace (kVA)  :

:

40) Butt-welding machine with DR-25%  :

:

The calculation of electrical loads of workshop

39) Plasma heating machine:

Distribution board:

32) Automatic lathes

36) Horizontal milling

40) Butt-welding machine with DR-25 %

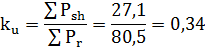

Total distribution board:

The exact value of m is not required, is sufficient to determine m>3 or m ≤3.

At m ≤ 3 effective number of electrical receivers is assumed equal to their actual number n: ne = n;

At m> 3 and group factor ku > 0.2 effective number of electrical receivers is defined by

from [table 3] maximum coefficient

from [table 3] maximum coefficient

At  ,

,

Table 3 – Selecting of maximum coefficient using ne and ku

| ne | Use factor ku | |||||||

| 0,1 | 0,15 | 0,2 | 0,3 | 0,4 | 0,5 | 0,6 | 0,7 and more | |

| 8,00 | 5,33 | 2,67 | 1,6 | 1,33 | 1,14 | |||

| 5,01 | 3,44 | 2,69 | 1,9 | 1,52 | 1,24 | 1,11 | ||

| 2,94 | 2,17 | 1,8 | 1,42 | 1,23 | 1,14 | 1,08 | ||

| 2,28 | 1,73 | 1,46 | 1,19 | 1,06 | 1,04 | 0,97 | ||

| 1,31 | 1,12 | 1,02 | 0,98 | 0,96 | 0,94 | 0,93 | ||

| 6-8 | 1,2 | 0,96 | 0,95 | 0,94 | 0,93 | 0,92 | 0,91 | |

| 9-10 | 1,1 | 0,97 | 0,91 | 0,9 | 0,9 | 0,9 | 0,9 | 0,9 |

| 10-25 | 0,8 | 0,8 | 0,8 | 0,85 | 0,85 | 0,85 | 0,9 | 0,9 |

| 25-50 | 0,75 | 0,75 | 0,75 | 0,75 | 0,75 | 0,8 | 0,85 | 0,85 |

| More than 50 | 0,65 | 0,65 | 0,65 | 0,7 | 0,7 | 0,75 | 0,8 | 0,8 |

Calculation of lighting load of the workshop

– area of production workshop;

– area of production workshop;

where kd.light.=0,85 – demand factor for active power of lighting load,  ,

,  – reactive power factor.

– reactive power factor.

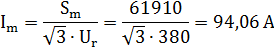

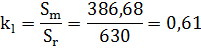

According to the calculations we select the transformer dry and protected (protective cover) type ТСЗ-630

– load factor, which should be in the range of 0.6 - 0.85.

– load factor, which should be in the range of 0.6 - 0.85.

Table 4 – The calculation of loads on the workshop

| № | Name of supply nodes and ER groups | n | Installed capacity, kW | Ки | cosφ | tgφ | Average powers | nэ | Км | n∙Рн2 | Ilong | Maximum design load | Id, А | |||||

| One ER | ∑Р | Рsh, kW | Qsh, kVar | Рм, kW | Qм, kVar | Sм, kVA | ||||||||||||

| Plasma heating machine | 0,25 | 0,65 | 1,16 | 22,50 | 26,10 | 1,00 | 4,00 | 8100,00 | 210,37 | 22,50 | 28,71 | 36,48 | 55,42 | |||||

| Distribution boards | ||||||||||||||||||

| Automatic lathes | 0,12 | 0,50 | 1,73 | 0,96 | 1,66 | 64,00 | 24,31 | |||||||||||

| Horizontal milling | 0,16 | 0,60 | 1,33 | 3,04 | 4,04 | 361,00 | 48,11 | |||||||||||

| Butt-welding machine with DR-25 % (kVA) | 17,5 | 17,5 | 0,25 | 0,70 | 1,02 | 4,38 | 4,46 | 306,25 | 37,98 | |||||||||

| Electric fan | 0,60 | 0,80 | 0,75 | 18,00 | 13,50 | 900,00 | 56,98 | |||||||||||

| Hull-grinding | 0,12 | 0,50 | 1,16 | 0,72 | 0,84 | 36,00 | 18,23 | |||||||||||

| Total distribution boards | =30/6>3 | 80,5 | 0,34 | 27,10 | 50,60 | 5,37 | 1,00 | 1667,25 | 185,61 | 27,10 | 55,66 | 61,91 | 94,06 | |||||

| Distribution busway 1 | ||||||||||||||||||

| 3,4 | Chamber electric furnace | 0,60 | 0,95 | 0,32 | 42,00 | 13,44 | 2450,00 | 55,98 | ||||||||||

| Bell-type electric furnace | 0,60 | 0,95 | 0,32 | 24,00 | 7,68 | 1600,00 | 63,97 | |||||||||||

| 6,7 | Mortising | 0,12 | 0,50 | 1,73 | 3,84 | 6,64 | 512,00 | 48,62 | ||||||||||

| 9,12,13,33 | Screw-cutting | 0,16 | 0,60 | 1,33 | 8,32 | 11,07 | 676,00 | 32,92 | ||||||||||

| 1,2 | Vertical milling | 0,16 | 0,60 | 1,33 | 5,76 | 7,66 | 648,00 | 45,58 | ||||||||||

| Circular shears | 0,16 | 0,60 | 1,33 | 2,72 | 3,62 | 289,00 | 43,05 | |||||||||||

| Crane with DR-40 % | 13,91 | 13,91 | 0,25 | 0,65 | 1,16 | 3,48 | 4,03 | 193,49 | 32,51 | |||||||||

| 8,16,17 | Circular grinding | 0,25 | 0,65 | 1,16 | 18,00 | 20,88 | 1728,00 | 56,10 | ||||||||||

| 10,11 | Hull-grinding | 0,12 | 0,5 | 1,16 | 1,44 | 1,67 | 72,00 | 18,23 | ||||||||||

| Radial-Drilling | 0,12 | 0,5 | 1,73 | 0,84 | 1,45 | 49,00 | 21,27 | |||||||||||

| Automatic lathes | 0,12 | 0,5 | 1,73 | 0,96 | 1,66 | 64,00 | 24,31 | |||||||||||

| 35,37 | Horizontal milling | 0,16 | 0,6 | 1,33 | 6,08 | 8,09 | 722,00 | 48,11 | ||||||||||

| Total distribution busway 1 | =40/6>3 | 397,91 | 0,30 | 117,44 | 87,89 | 11,05 | 0,75 | 490,65 | 88,08 | 87,89 | 124,43 | 189,05 |

Table 4 continuation – The calculation of loads on the workshop

| distribution busway 2 | |||||||||||||||||

| 21,22,25 | Chamber electric furnace | 0,60 | 0,95 | 0,32 | 63,00 | 20,16 | 3675,00 | 55,98 | |||||||||

| 19,20 | Crank Press | 0,16 | 0,6 | 1,33 | 4,80 | 6,38 | 450,00 | 37,98 | |||||||||

| 28,29 | Shaping-machine | 0,25 | 0,65 | 1,16 | 10,50 | 12,18 | 882,00 | 49,09 | |||||||||

| Crane with DR-40 % | 13,91 | 13,91 | 0,25 | 0,5 | 1,73 | 3,48 | 6,02 | 193,49 | 42,27 | ||||||||

| 23,24 | Bell-type electric furnace | 0,60 | 0,95 | 0,32 | 48,00 | 15,36 | 3200,00 | 63,97 | |||||||||

| Induction furnace | 35,75 | 35,75 | 0,25 | 0,65 | 1,16 | 8,94 | 10,37 | 1278,06 | 83,56 | ||||||||

| Circular shears | 0,16 | 0,6 | 1,33 | 2,72 | 3,62 | 289,00 | 43,05 | ||||||||||

| Radial-Drilling | 0,12 | 0,5 | 1,73 | 0,84 | 1,45 | 49,00 | 21,27 | ||||||||||

| Total distribution busway 2 | =40/7>3 | 330,66 | 0,43 | 142,28 | 75,54 | 6,30 | 0,85 | 120,93 | 83,09 | 146,73 | 222,93 | ||||||

| Lighting board | 17,14 | 5,65 | 17,14 | 5,65 | 17,14 | 26,00 | |||||||||||

| Total TSS | =90/6>3 | 899,07 | 0,34 | 309,31 | 240,13 | 17,13 | 0,75 | 231,98 | 240,13 | 333,88 | 507,28 |

Table 5 - Technical data of electroreceivers

| № | Name of supply nodes and ER groups | Рr | Ir | Кcor | Istart | Mode | α | Istart /α | Type of protection | |

| Plasma heating machine | 210,37 | 631,11 | Hard start | 1,6 | 394,44 | circuit breaker | ||||

| Distribution boards | ||||||||||

| Automatic lathes | 24,31 | 145,86 | Easy start | 2,5 | 58,34 | fuse | ||||

| Horizontal milling | 48,11 | 192,45 | Medium start | 96,23 | fuse | |||||

| Butt-welding machine with DR-25 % (kVA) | 17,5 | 37,98 | 113,95 | Medium start | 71,22 | fuse | ||||

| Electric fan | 56,98 | 170,93 | Hard start | 1,6 | 106,83 | fuse | ||||

| Hull-grinding | 18,23 | 109,39 | Easy start | 2,5 | 43,76 | Fuse | ||||

| Distribution busway 1 | ||||||||||

| 3,4 | Chamber electric furnace | 55,98 | 55,98 | - | 1,6 | 34,98 | circuit breaker | |||

| Bell-type electric furnace | 63,97 | 63,97 | - | 2,5 | 25,59 | circuit breaker | ||||

| 6,7 | Mortising | 48,62 | 194,48 | Medium start | 97,24 | Fuse | ||||

| 9,12,13,33 | Screw-cutting | 32,92 | 131,68 | Medium start | 65,84 | Fuse | ||||

| 1,2 | Vertical milling | 45,58 | 182,32 | Medium start | 91,16 | Fuse | ||||

| Circular shears | 43,05 | 172,19 | Medium start | 86,10 | Fuse | |||||

| Crane with DR-40 % | 13,91 | 32,51 | 130,06 | Medium start | 65,03 | Fuse | ||||

| 8,16,17 | Circular grinding | 56,10 | 168,30 | Hard start | 1,6 | 105,19 | circuit breaker | |||

| 10,11 | Hull-grinding | 18,23 | 109,39 | Easy start | 2,5 | 43,76 | Fuse | |||

| Radial-Drilling | 21,27 | 127,62 | Easy start | 2,5 | 51,05 | Fuse | ||||

| Automatic lathes | 24,31 | 145,86 | Easy start | 2,5 | 58,34 | Fuse | ||||

| 35,37 | Horizontal milling | 48,11 | 192,45 | Medium start | 96,23 | Fuse | ||||

| distribution busway 2 | ||||||||||

| 21,22,25 | Chamber electric furnace | 55,98 | 55,98 | - | 1,6 | 34,98 | circuit breaker | |||

| 19,20 | Crank Press | 37,98 | 151,93 | Medium start | 75,97 | Fuse | ||||

| 28,29 | Shaping-machine | 49,09 | 147,26 | Hard start | 1,6 | 92,04 | Fuse | |||

| Crane with DR-40 % | 13,91 | 42,27 | 169,07 | Medium start | 84,54 | Fuse | ||||

| 23,24 | Bell-type electric furnace | 63,97 | 63,97 | - | 2,5 | 25,59 | circuit breaker | |||

| Induction furnace | 35,75 | 83,56 | 250,69 | Hard start | 1,6 | 156,68 | circuit breaker | |||

| Circular shears | 43,05 | 172,19 | Medium start | 86,10 | Fuse | |||||

| Radial-Drilling | 21,27 | 127,62 | Easy start | 2,5 | 51,05 | Fuse |

The calculation of the technical data for power consumers and the choice of protective devices

Selecting of circuit breakers for ER №39 is made according on the following conditions:

|

|

|

|

|

|

Selection of the fuses for ER №32 is made according on the following conditions:

|

|

|  4 4

|

Selecting the wire to the electrical receiver №32 and cable to the load nodes is made according to the following conditions:

|

|

|

|

Where  – protection current of fuse,

– protection current of fuse,

– protection factor,

– protection factor,

– correcting coefficient on the conditions of installation of wiring and cables

– correcting coefficient on the conditions of installation of wiring and cables

Table 6 - table of correcting factor

| The distance between cables in the light | Correcting coefficient at the number of cables | |||||

| 0,9 | 0,85 | 0,8 | 0,78 | 0,75 | ||

| 0,92 | 0,87 | 0,84 | 0,82 | 0,81 | ||

| 0,93 | 0,9 | 0,87 | 0,86 | 0,85 |

the choice of circuit breaker, cable and type of busbars

Distribution board:

Selecting of circuit breaker ВА 51-31-1 for distribution board is made according on the following conditions

|

|

|

|

|

|

For given power node we should select distribution board ПР8501-002-21УЗ

|

|

For given power node we select cable ААБГ 3х25

|

|

|

|

Distribution busway 1

Selecting of circuit breaker ВА 51-35 for distribution busway is made according on the following conditions

|

|

|

|

|

|

For given power node we should select distribution busway КОА0155-II-STD

|

|

For given power node we select cable ААБГ 3х70

|

|

|

|

Distribution busway 2

Selecting of circuit breaker ВА 51-35 for distribution busway is made according on the following conditions

|

|

|

|

|

|

For given power node we should select distribution busway КОА0155-II-STD

|

|

For given power node we select cable ААБГ 3х95

|

|

|

|

Lighting load:

Selecting of circuit breaker ВА 51-35 for lighting load is made according on the following conditions

|

|

|

|

|

|

For given power node we should select distribution busway ПР8501-002-21УЗ

|

|

For given power node we select cable ААБГ 3х2,5

|

|

|

|

Mains distribution busway

Selecting of circuit breaker ВА 51-39 for mainsdistribution busway is made according on the following conditions

|

|

|

|

|

|

For given power node we should select main busway MR 160-800

|

|

Table 7 – Calculation of protective devices to ER

| № | Design current, А | Circuit breaker | Fuse | Type of protection device | Кprot | Wires's current load | Кcor | Ipem.busway | Mark and conductor cross-section | |||||||||

| Ilong | Istart | Ir.c.b., А | Tripping current, А | Installation of instant trigger, А | Fuse current, А | Ir.fuse, А | (Кprot∙Iprot)/Кcor | Istart/ Кcor | ||||||||||

| Id.tip | Ir.tip | Itrigger tip | Ir.tip | Id.fuse-link | Ir.fuse-link | |||||||||||||

| 210,37 | 631,11 | 210,37 | 788,89 | ВА51-35 | 0,22 | 55,00 | 210,37 | ААБГ-3х120 | ||||||||||

| Distribution board | ||||||||||||||||||

| 24,31 | 145,86 | 58,34 | НПН2 | 0,33 | 26,65 | 31,17 | 0,78 | АППВ-4х10 | ||||||||||

| 48,11 | 192,45 | 96,23 | ПН2 | 0,33 | 42,31 | 61,68 | 0,78 | АППВ-4х25 | ||||||||||

| 37,98 | 113,95 | 71,22 | ПН2 | 0,33 | 42,31 | 48,70 | 0,78 | АППВ-4х16 | ||||||||||

| 56,98 | 170,93 | 106,83 | ПН2 | 0,33 | 52,88 | 73,05 | 0,78 | АППВ-4х35 | ||||||||||

| 18,23 | 109,39 | 43,76 | НПН2 | 0,33 | 26,65 | 23,37 | 0,78 | АППВ-4х4 | ||||||||||

| Distribution busway 1 | ||||||||||||||||||

| 3,4 | 55,98 | 167,93 | 55,98 | 209,91 | ВА-51-31-1 | 0,22 | 18,48 | 74,63 | 0,75 | АППВ-4х35 | ||||||||

| 63,97 | 383,83 | 63,97 | 479,79 | ВА-51-31-1 | 0,22 | 29,33 | 85,30 | 0,75 | АППВ-4х50 | |||||||||

| 6,7 | 48,62 | 194,48 | 97,24 | ПН2 | 0,33 | 44,00 | 64,83 | 0,75 | АППВ-4х25 | |||||||||

| 9,12,13,33 | 32,92 | 131,68 | 65,84 | ПН2 | 0,33 | 35,20 | 43,89 | 0,75 | АППВ-4х16 | |||||||||

| 1,2 | 45,58 | 182,32 | 91,16 | ПН2 | 0,33 | 44,00 | 60,77 | 0,75 | АППВ-4х25 | |||||||||

| 43,05 | 172,19 | 86,10 | ПН2 | 0,33 | 44,00 | 57,40 | 0,75 | АППВ-4х25 | ||||||||||

| 32,51 | 130,06 | 65,03 | ПН2 | 0,33 | 35,20 | 43,35 | 0,75 | АППВ-4х16 | ||||||||||

| 8,16,17 | 56,10 | 168,30 | 56,10 | 210,37 | ВА-51-31-1 | 0,22 | 18,48 | 74,80 | 0,75 | АППВ-4х35 | ||||||||

| 10,11 | 18,23 | 109,39 | 43,76 | НПН2 | 0,33 | 27,72 | 24,31 | 0,75 | АППВ-4х4 | |||||||||

| 21,27 | 127,62 | 51,05 | НПН2 | 0,33 | 27,72 | 28,36 | 0,75 | АППВ-4х6 | ||||||||||

| 24,31 | 145,86 | 58,34 | НПН2 | 0,33 | 27,72 | 32,41 | 0,75 | АППВ-4х10 | ||||||||||

| 35,37 | 48,11 | 192,45 | 96,23 | ПН2 | 0,33 | 44,00 | 64,15 | 0,75 | АППВ-4х25 | |||||||||

| Distribution busway 2 | ||||||||||||||||||

| 21,22,25 | 55,98 | 167,93 | 55,98 | 209,91 | ВА-51-31-1 | 0,22 | 17,33 | 69,97 | 0,8 | АППВ-4х25 | ||||||||

| 19,2 | 37,98 | 151,93 | 75,97 | ПН2 | 0,33 | 41,25 | 47,48 | 0,8 | АППВ-4х16 | |||||||||

| 28,29 | 49,09 | 147,26 | 92,04 | ПН2 | 0,33 | 41,25 | 61,36 | 0,8 | АППВ-4х25 | |||||||||

| 42,27 | 169,07 | 84,54 | ПН2 | 0,33 | 41,25 | 52,84 | 0,8 | АППВ-4х25 | ||||||||||

| 23,24 | 63,97 | 383,83 | 63,97 | 479,79 | ВА-51-31-1 | 0,22 | 22,00 | 79,97 | 0,8 | АППВ-4х35 | ||||||||

| 83,56 | 250,69 | 83,56 | 313,36 | ВА-51-31-1 | 0,22 | 27,50 | 104,45 | 0,8 | АППВ-4х50 | |||||||||

| 43,05 | 172,19 | 86,10 | ПН2 | 0,33 | 41,25 | 53,81 | 0,8 | АППВ-4х25 | ||||||||||

| 21,27 | 127,62 | 51,05 | НПН2 | 0,33 | 25,99 | 26,59 | 0,8 | АППВ-4х6 | ||||||||||

Table 7 – Calculation protective devices to DB, DBW, LL, DMBW

| № | Design current, А | Circuit breaker | Type of protection device | Кprot | Current load of wires | Кcor | Ipem.busway. | Mark and conductor cross-section | Ilong DB | Name | ||||||

| Ilong | Istart | Ir.cb, А | Tripping current, А | Installation of instant trigger, А | (Кprot∙Iprot)/Кcor | Istart/ Кcor | ||||||||||

| Id.tip | Ir.tip | Itrigger tip | Ir.tip | |||||||||||||

| DB | 94,06 | - | 94,06 | 412,44 | ВА51-31-1 | 0,22 | 94,06 | ААБГ-3х25 | ПР8501-002-21УЗ | |||||||

| DBW1 | 189,05 | - | 189,05 | 1547,49 | ВА51-35 | 0,22 | 189,05 | ААБГ-3х70 | КОА0155-II-STD | |||||||

| DBW2 | 222,93 | - | 222,93 | 1225,03 | ВА51-33 | 0,22 | 222,93 | ААБГ-3х95 | КОА0155-II-STD | |||||||

| LL | - | 31,5 | 26,00 | 94,5 | ВА51-31-1 | 0,22 | 6,93 | ААБГ-3х2,5 | ПР8501-002-21УЗ | |||||||

| Total TSS | 507,28 | - | 507,28 | 2475,98 | ВА51-39 | 0,22 | 138,6 | 507,28 | - | - | MR 160-800 |

Calculation of short circuit currents

Figure 2 - design scheme

Calculation of resistance on the circuit area

Figure 3- the equivalent circuit

We expect resistance at TS Δ/Y0:

;

;

;

;

We expect resistance to the distribution busway MR:

;

;

;

;

.

.

We expect resistance circuit breaker ВА 51-39

For a circuit breaker with a rated current 630 А:

;

;

;

;

Area 2

We expect resistance circuit breaker ВА 51-35

For a circuit breaker with a rated current 250 А:

;

;

;

;

We expect the cable resistance ААБГ 3х70:

;

;

;

;

We expect resistance to the distribution busway KOA0155-II-STD:

;

;

;

;

.

.

Area 1

We expect resistance circuit breaker BA 51-31-1:

;

;

;

;

We expect the cable resistance AППВ 4х35:

;

;