FERROUS METALS. CAST IRON.

VOCABULARY

a large factor of safety — большой коэффициент безопасности

it is used much — он широко используется

lb. per square inch — фунт на квадратный дюйм

in the matter of — в отношении

iron – железо

сarbon - углерод

silicon - кремний

steel- сталь

cast iron – чугун

pig iron – первичный чугун

blast furnace – доменная печь

mould – форма casting- литье

solidify – затвердевать

foundry – литейный завод

malleable iron - ковкий чугун

grey iron – серый литейный чугун

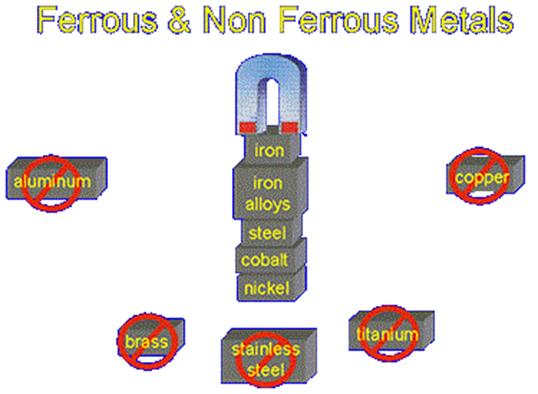

What is the difference between ferrous and non-ferrous metals?

Ferrous metals contain iron and non-ferrous metals do not. Non-ferrous metals are rarer, more valuable and resistant to corrosion, than ferrous metals. Ferrous and non-ferrous metals are both recyclable.

Magnetising the iron in ferrous metals can separate ferrous and non-ferrous metals.

Ferrous metals consist of iron combined with carbon, silicon, phosphorus and other elements. Carbon is the most important of all elements present in ferrous alloys. Ferrous metals are used in industry in two general forms which differ in the quantity of carbon content.

steel

steel

cast iron

cast iron

These two ferrous alloys are derived from pig iron which is produced in a blast furnace in the form of pigs. Metals are usually melted and poured into a form which is called a "mould". This process is known as casting. The cast metal is shaped in the mould where it cools and solidifies. Thus one can cast different objects known as castings. The shop where metals are cast is called a "foundry". Castings are used in building engines, automobiles and airplanes, and different types of machinery.

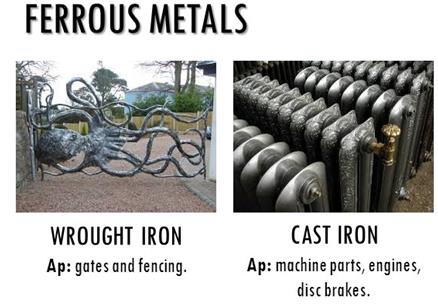

Cast iron contains more than 2.0 per cent. It is very cheap, in fact, it is the cheapest of all the engineering metals used in machine-building. There are two major types of iron produced: wrought iron and cast iron. Within those, cast iron includes its own family of metals. People often assume that cast iron and wrought iron are interchangeable terms for early iron work, but there is a world of difference.

Wrought Iron is iron that has been heated and then worked with tools.

Cast Iron is iron that has been melted, poured into a mold, and allowed to solidify.

The fundamental distinction between cast iron and wrought iron is in how they are produced. The differences can be found in the names: wrought is a past participle of work (“worked iron”), and cast describes anything formed by the casting process.

What is wrought iron?

Wrought iron was used as early as 2000 BC in the Anatolian peninsula (now Turkey), and it was widely used in construction throughout the 19th century. Advancements in metallurgy in the 20th century, however, have made it easier and less expensive to machine-form and weld metal parts. The comparatively expensive and time-consuming nature of blacksmithing led to the end of its large scale commercial practice in the mid-1970s. This means that most true wrought-iron pieces today are either antiques or a specialty pieces that have been smithed by local artisans.

Wrought iron is composed primarily of elemental iron with small amounts (1–2 percent) of added slag (the by-product of iron ore smelting, generally consisting of a mixture of silicon, sulfur, phosphorous, and aluminum oxides). Wrought iron is made by repeatedly heating the material and working it with tools to deform it.

Wrought iron is highly malleable, allowing it to be heated, and re-heated, and worked into various shapes—wrought iron grows stronger the more it’s worked and is characterized by its fibrous appearance. Wrought iron contains less carbon than cast iron, making it softer and more ductile. It is also highly resistant to fatigue; if large amounts of pressure are applied, it will undergo a large amount of deformation before failing.

The term “wrought iron” is often misused today; it is commonly used to describe designs similar to historical wrought iron pieces—regardless of the metal used. Mild steel that has been machine-bent into shape in a cold state or cast steel and iron pieces that have been painted black are both regularly mislabelled as wrought iron work. To be truly designated as wrought iron, however, a metal piece must be forged by a blacksmith who heats it and hammers it into shape.

What is cast iron?

Cast iron is produced by smelting iron-carbon alloys that have a carbon content greater than 2%. After smelting, the metal is poured into a mold. The primary difference in production between wrought iron and cast iron is that cast iron is not worked with hammers and tools. There are also differences in composition—cast iron contains 2–4% carbon and other alloys, and 1–3% of silicon, which improves the casting performance of the molten metal. Small amounts of manganese and some impurities like sulfur and phosphorous may also be present. Differences between wrought iron and cast iron can also be found in the details of chemical structure and physical properties. Various types of cast irons are produced using different heat treatment and processing techniques, including

gray iron,

gray iron,

white iron,

white iron,

malleable iron,

malleable iron,

ductile iron,

ductile iron,

compacted graphite iron.

compacted graphite iron.

Cast iron and wrought iron are both susceptible to corrosion when bare surfaces are exposed to oxygen in the presence of moisture. This can be challenging for outdoor environments with near-constant exposure to precipitation and humidity. Unlike other metals that form a protective oxidative coating, iron will, given enough time, rust and flake away entirely.

To prevent rust, iron products should be coated to prevent exposure. Paint is commonly used to coat and protect bare metal. Powder coating is another method, ideal for outdoor furnishings more susceptible to wear in high-traffic areas. Powder coatings are highly durable and won’t fade, chip or crack over extended periods of time.

EXERCISES