Практическое занятие №148

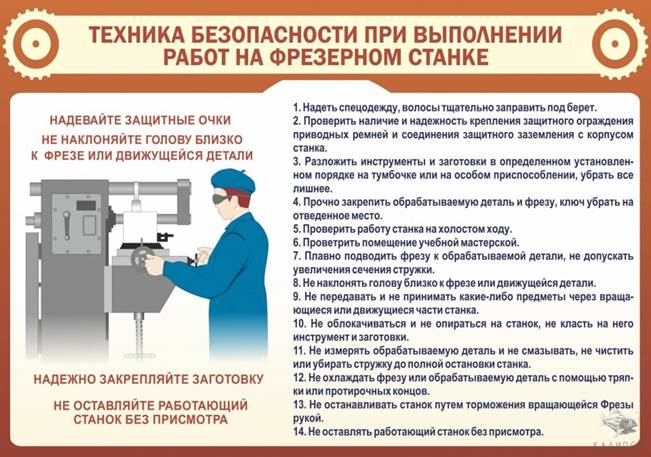

Тема: «Правила техники безопасности при работе на фрезерном станке»

Задание: прочтите текст, на его основе составьте инструкцию по технике безопасности при работе на фрезерном станке на английском языке:

Safety rules when working on a milling machine

Workers who have received special training, including in educational institutions, are allowed to work on the milling machine. Obligatory condition:

• age over 18 years;

• electrical safety tolerance-group II and higher;

• passing a medical examination;

• passing safety instructions — primary (in accordance with regulatory documents) and secondary;

* knowledge and compliance with fire safety measures;

• passing an internship;

* passing the set-off for labor protection.

Preparation for work

Before proceeding to the direct processing of blanks, the specialist must perform the following actions:

1. Wear protective clothing and personal protective equipment (glasses, face shield, half or full mask, boots, gloves, etc.). The hair must be completely tucked under the headdress.

2. Check the ground connection (correct connection to the housing, integrity) and the protective protection of the drive belts.

3. Prepare the necessary tools — only those that are required to perform a specific job.

4. Secure the workpiece and check its reliability.

5. Check the cooling systems (including the working fluid on some machines).

6. To run a milling machine at idle speed for some models — with the inclusion of self-test capabilities. Evaluate the condition of controls and the operation of moving elements.

The free rotation of the spindle is checked manually. The tool portal must be in the upper position to avoid the destruction of the cutter.

Prevent:

• using a faulty tool;

• presence of chips and deformations on the cutting elements;

• presence of potholes, cracks and other defects on the spanners, loosening of moving parts;

* presence of cracks, burrs and sharp edges on the manually supported sections.

If any problems with the equipment are detected or there is a risk to the health and life of people, you must immediately stop working and notify the management.

Safety measures during operation

If the direction of rotation of the CNC milling machine and the feed of the workpiece coincide, there is a possibility of damage to the teeth: on conventional equipment, the part must be fed in the opposite direction. Passing milling is possible on special machines.

Other safety measures that are important to observe directly during operation:

• as soon as there is a runout or vibration of the milling machine, the equipment must be stopped immediately (for this purpose, milling machines are equipped with fast-acting braking devices);

• while the machine is running, it is strictly forbidden to perform lubrication and cleaning, maintenance of the cooling system;

• it is not allowed to remove the fence;

* removal of machine parts from the spindle is performed using a special knockout; previously, a wooden lining must be installed on the work table;

• during high-speed milling, it is mandatory to use chip collectors, special flaps and screens;

• all moving parts (transmission shafts, spindles, etc.) must be protected.

This is strictly forbidden:

• undertake manipulation of the cutter without the use of protective devices,

* remove safety devices and barriers until the equipment stops working completely,

* leave milling equipment unattended on a moving table,

• use cutters with damaged teeth.

Special attention should be paid to moving parts and details — they are the most common cause of injuries.

Домашнее задание:

выполнить письменный перевод текста « Protective equipment and measures »